Aws Cwi Things To Know Before You Buy

Aws Cwi Things To Know Before You Buy

Blog Article

A Biased View of Aws Cwi

Table of ContentsSome Known Facts About Aws Cwi.7 Easy Facts About Aws Cwi ExplainedHow Aws Cwi can Save You Time, Stress, and Money.The Ultimate Guide To Aws CwiAws Cwi Fundamentals Explained

Third-party high quality control assessment of steel fabrication facilities on welding examination, as well as examination of bolting and painting of structural steel. KTA's steel assessors give Quality assurance (QC) assessors to supplement fabricator's/ professional's in-house QC team and on projects that mandate preserving the solutions of a certified examiner (e.g., CWI) used by an independent examination company.Examiners carry out aesthetic evaluations of product for correspondence with the approved specs, plans and codes, in addition to verification of Licensed Product Examination Reports (CMTR) for materials utilized. Materials and elements are observed at key factors along the production process in both steel mills and steel fabrication shops. KTA's certified welding examiners also witness welder and welding treatment certification examinations as applicable to the extent of the job.

Steel manufacture inspection services also regularly include doing non-destructive testing (NDT), additionally called non-destructive exam (NDE), including Magnetic Bit Testing (MT), Ultrasonic Screening (UT) and Fluid Penetrant Evaluating (PT) (Certified Welding Inspection). Examinations happen in steel mills and manufacture shops throughout the United States and on-site in the field and include all ranges of frameworks consisting of bridges, arenas, structures, towers, posts, and indication frameworks

The Of Aws Cwi

KTA supplies inspection solutions for the manufacture of bridge girders, bearings, grid deck, sign structures, light and web traffic poles, pedestrian bridges, and various other freeway components. KTA also offers these services for construction of structural steel for structures, tanks and pipelines. KTA's assessment solutions consist of covering evaluations covering surface area preparation, painting, galvanizing, and metalizing.

KTA's approach is to react rapidly to customers' needs, match the best examiner to the job, and offer the requisite documents. KTA has the assistance personnel to supply technical consulting to the area personnel and to the client. KTA has professionals readily available to consult on welding, NDT and coverings.

FST Technical Services is your global partner in the Semiconductor and Drug Industries! Our placements include advantages such as clinical, dental, vision, life, 401(k) with firm match, PTO, paid holidays. Come join a remarkable team in an amazing, fast paced, and ever-growing sector! We are seeking a CWI's and/or NDT Level II certified Welding Inspectors from around the Lithia Springs, GA area! Neighborhood area candidates are motivated to use yet this placement is open to travelers with mobilization and monthly per diem for those living outside the area.

Aws Cwi - An Overview

Suitable prospect will certainly have high purity piping evaluation experience. CWI's and NDT Level II's very encouraged to use.

Pro QC's third-party welding evaluation solutions consist of: Paper Evaluation Witness Inspections Visual Inspections Dimensional Inspections Non-Destructive Testing (NDT) Others Our welding assessment records are delivered within 24 hr and record all assessment points pertinent to top quality, including all determined weld flaws and electronic pictures (Weld Inspector) (https://www.video-bookmark.com/bookmark/6408477/aws-cwi/). Pro QC's group of assessors supplies third-party welding inspections throughout the globe, in China, India, Indonesia, Malaysia, Thailand, Vietnam, Singapore, South Korea, Turkey, UAE, Jordan, Egypt, South Africa, Morocco, Algeria, Tunisia, France, Germany, Italy, Czechia, Hungary, Spain, Sweden, Portugal, the Netherlands, Denmark, Norway, Finland, Belgium, the United Kingdom, Serbia, Greece, Romania, Bulgaria, Ukraine, Slovenia, Slovakia, Poland, Croatia, Russia, Lithuania, the United States, Mexico, copyright, Brazil, Peru, and a lot more countries

Evaluation of the welding work is vital for proper high quality When your business is dealing with significant tasks with requirements for 3rd celebration independent welding evaluation, we provide outstanding welding witness inspection services to verify that welding has actually been done according to a lot of used welding criteria and specs. AQSS carries out welding examination solutions for clients from a selection of industries.

Aws Cwi Fundamentals Explained

Not following appropriately certified welding procedures commonly causes a weld of below average quality, which can enhance the construction's possibility of failing under designated solution problems. By inspecting for problems, our assessors can help customers guarantee that their welds satisfy appropriate standards of quality control (Weld Inspection). Weld inspections are conducted for several reasons, one of the most common of which is to establish whether the weld is of appropriate high quality for its intended application

The code and typical utilized depends on the industry. Our welding examiners have actually the called for qualifications with years of experience with examination and recognize with many used welding requirements and specs. AQSS has CWI certified inspectors as well. We execute these services utilizing a variety of nondestructive screening (NDT) techniques: The assessment is performed based on appropriate codes, such as American Welding Society (AWS), American Society of Mechanical Engineers (ASME), and Military (MIL-STD) basic Carpet cleaning Portsmouth requirements.

The smart Trick of Aws Cwi That Nobody is Discussing

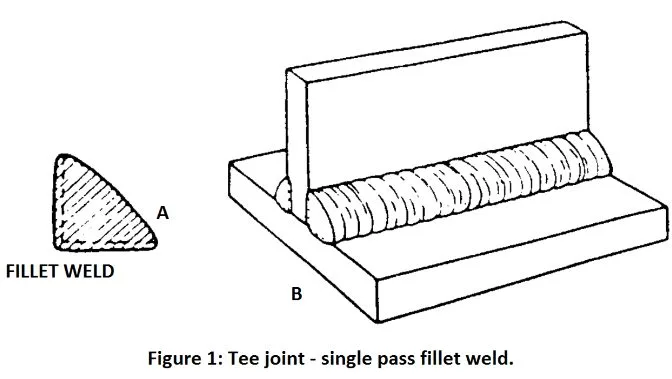

Weld examination of laser and electron beam of light bonded components normally adheres to 3 unique paths: aesthetic assessment; devastating screening; and non-destructive screening (NDT). includes taking a look at a weld with the naked eye and/or with some level of magnification. Generally, our inspectors are checking for cracks, pits, surface pores, undercut, underfill, missed joints, and other elements of the weld.

Samples can additionally be taken at intervals during the production procedure or at the end of the run. Destructive testing samples are exactly cut, machined, ground, and polished to a mirror-like surface. An acid etch is after that related to visually highlight the weld, and the example is then evaluated under a microscope.

Report this page